Function and installation

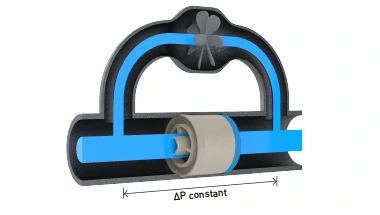

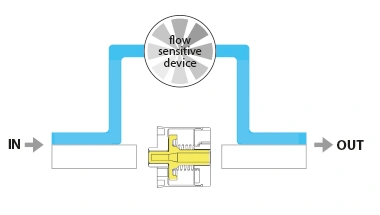

HDS bypass valves open as soon as the water pressure reaches a level defined by means of the force of the installed spring.

The more water flows, the wider the valve opens. The excess water is diverted past the main pipe with the device (pump or turbine), where the pressure and flow rate remain constant.

HDS bypass valves are installed in the flow direction.